Hands-on Engineering Projects Offer Real-world Problem Solving Experience

Through team-based and individual challenges, RVCC’s Engineering students were introduced to real-world problem solving in 2017-2018, resulting in another year of great scientific successes.

Students participating in Professor Peter Stupak’s Authentic Engineering Experience teamed in groups of 2-4 to make a real product for an actual customer in one semester. Working with the customer, students designed a prototype, made changes based on feedback, and delivered the product on deadline. Four Authentic Engineering team projects were completed for customers that included LabCorp and Duke Farms Foundation, as well as members of the RVCC community. The hands-on projects were all funded by the RVCC Foundation.

LabCorp, a leading global life sciences company that is deeply integrated in guiding patient care through comprehensive clinical laboratory and end-to-end drug development services, engaged an RVCC team of three Engineering students to improve the throughput of a part of one of its processes. The RVCC team developed three separate prototype solutions and presented its results to the LabCorp Operations and Management teams. Impressed by the students’ work, LabCorp, which has a large regional laboratory in Raritan, hired all three students as summer 2018 interns to implement the selected prototype solution into the process. Working directly with the LabCorp team, the RVCC students experienced firsthand the work and responsibilities of process engineers and have completed a production-ready prototype and are currently testing the unit in the process.

Duke Farms of Hillsborough, a nationally known nature stewardship and educational foundation, engaged a three-student RVCC team to develop and deliver firefly simulators to be used by the public at Duke Farms’ annual “Firefly Festival” in July. The simulators were required to be “green” and sustainable using natural materials and no batteries. The RVCC team developed simulators for five firefly species, accounting for the variances in color, pattern and timing of the “lights” of the actual species. The flashing of the firefly lights was simulated by LEDs powered by battery-free “green energy,” which was created by shaking the simulator to move a magnet through wire coils. The Firefly Project met with great success: Approximately 1,700 people attended each night of the two-night Festival and all ages tried out the simulators.

Kate Reilly, Manager of Education at Duke Farms, said that the team’s work was an “educational highlight of the year and directly aligned to Duke Farms’ mission statement: ‘to serve as a model of environmental stewardship, and to inspire our visitors to become informed stewards of the land.’”

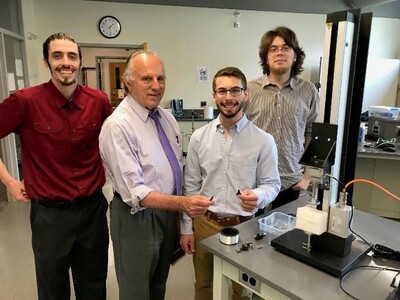

Two additional projects this year focused on customers within the College community. A team of three Engineering students created a Uniaxial Materials Strength Testing Machine for use in RVCC’s new Materials Testing Laboratory. The laboratory was developed to support the College’s Engineering Mechanics and Materials courses, and the machine is a vital part of the lab. A typical base model costs between $20,000-$25,000, but the student team made a fully functional machine for less than $6,000.

An Engineering & Visual Communication collaboration in fall 2017 resulted in a practical “Backpacking Tent-Light” that provides 30 minutes of green-energy, battery-free illumination for a backpacking mountain-tent environment. Originally conceived by a former RVCC Visual Communication student, the Backpacking Tent-Light collaboratively engaged two RVCC Engineering students and a class of nine Visual Communication majors, led by Professor Darren McManus. The teams’ collaboration resulted in an attractive, superior-functioning product that would not have been possible had the Engineering team worked alone. The project was the second collaborative effort between Professors McManus and Stupak that introduced students to cross-disciplinary teamwork to achieve a superior product development. Its success was further recognized after it was published at the American Society of Engineering Education’s 2018 Northeast Section (ASEE-NE) Conference.

Several RVCC Engineering students also gained hands-on experience in scientific exploration during the 2017-2018 school year by participating in independent projects. Esther Hiamang earned Second Place honors (Graduate Division) at the ASEE-NE’s Conference for her paper, “Contactless Magnetic Gears – A Project Based Learning Approach to Understanding Magnetic Gear Systems.” The work also was published in the Conference Proceedings. Interested in learning more about mechanical gear systems and magnetism, Esther investigated a system of mechanical gears that uses non-contact magnetic “gear teeth” instead of normal physical gear teeth. Focusing her research on such subjects as magnetic fields, force and motion, she used theoretical analysis and construction of a contactless magnetic gear system to obtain results.

In addition, several students worked with Professor Stupak to complete their independent Honors Capstone projects:

• Laser Art and Poetry – A Tribute: Using an RVCC student-developed laser-audio system, Lauren Wougk encoded recorded poetry readings onto a laser-beam and projected them onto solar cells positioned on painted artistic panels. The words were spoken by people in Lauren’s life who had influenced her success, and each panel—which she painted herself—represented a different person. The solar cells received and converted the laser signal into audio. The laser was mounted on a programmable motor that positioned the laser so that it would move in time with the recorded poetry. Lauren’s work was featured in the RVCC Student Art Show in April 2018.

• Modified Suspension System for Tracked Vehicles: Feodor Tzabrov physically constructed one side of a tracked vehicle. His modification of the suspension system demonstrated that in the event the track was removed, the vehicle could operate using road wheels.

• Particle Trajectory Deviation Using Static Electric Fields: A master of model-making, Jeshua Rodriguez investigated the steering of a stream of charged paint particles to a target using external electric fields. Jeshua crafted experimental models to test all possible sources of interference in his experiment. He achieved near 90-degree deflection of positive and negative paint particles.